Modern agriculture faces a paradox: technological advances have boosted crop yields, yet conventional practices often cause soil degradation, overuse of fertilizers, and loss of biodiversity. Precision agriculture seeks to resolve these challenges by utilizing real-time data to optimize farming decisions. Central to this approach is soil health monitoring.

Traditional methods, such as soil sampling and laboratory analysis, are labor-intensive, costly, and fail to provide continuous insights into dynamic soil conditions. Without timely data, irrigation, fertilization, and pesticide applications are often based on estimates, leading to inefficiencies and environmental harm. Biodegradable sensors offer a transformative solution, providing continuous, real-time monitoring while naturally decomposing in the soil. These innovative tools enhance agricultural efficiency, sustainability, and long-term soil conservation.

Read More: Finding the Right Soil Sensor for Your Farm

Understanding Biodegradable Sensors

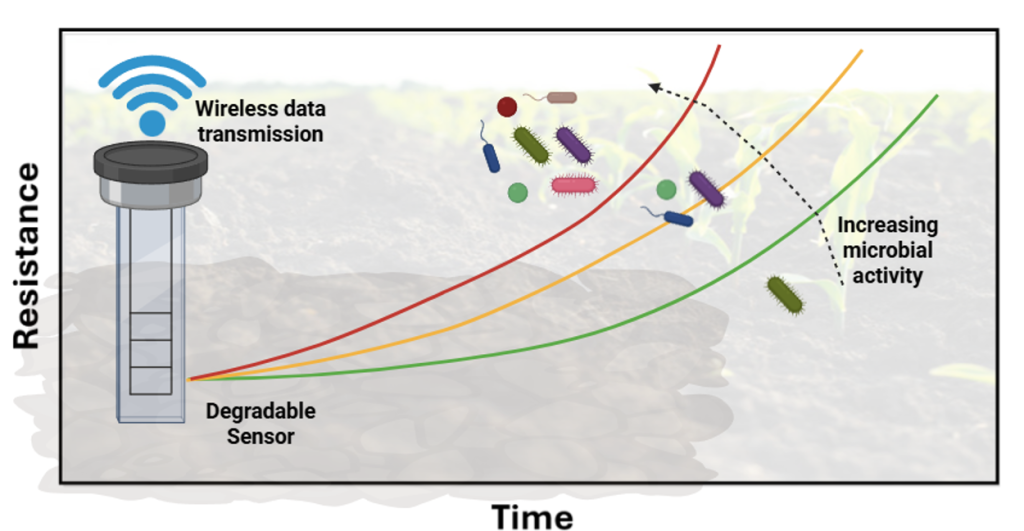

Biodegradable sensors operate by embedding conductive materials within a degradable matrix. Environmental factors such as microbial activity, moisture variations, or chemical interactions gradually break down this matrix, leading to measurable changes in the sensor’s electrochemical properties. For example, as the conductive network deteriorates, the sensor’s electrical resistance typically increases.

By monitoring and quantifying these changes, researchers and farmers can obtain real-time insights into soil conditions, moisture levels, nutrient dynamics, and other critical environmental factors. This ability to track dynamic processes continuously—without leaving harmful residues—makes biodegradable sensors a powerful tool for sustainable and precise agricultural monitoring.

How Do They Work?

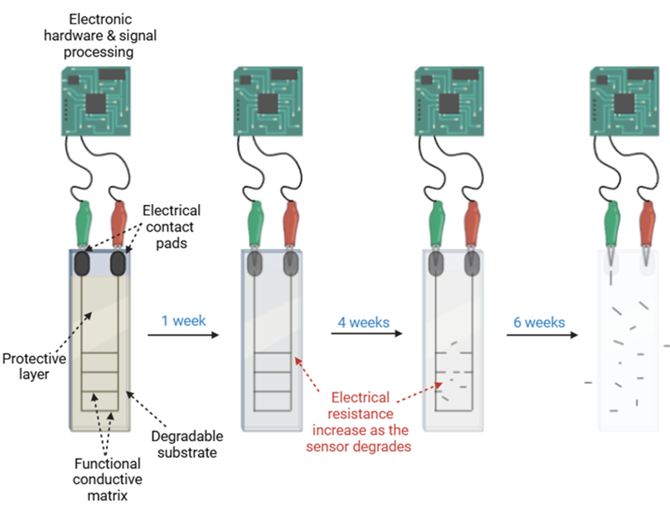

Biodegradable sensors are constructed from three essential components, each optimized for both degradability and functionality according to the intended application.

Substrate: Serving as the sensor’s foundation, the substrate provides mechanical support and structural integrity while remaining biodegradable. Common materials include biopolymers, cellulose-based films, or naturally degradable substrates. It must balance operational stability with controlled degradation to minimize environmental impact.

Functional Component: This is the active sensing element that detects environmental changes. It typically consists of conductive biodegradable materials, such as carbon-based composites, metal nanoparticles, or polymeric conductors, which respond to environmental stimuli by altering their electrical properties.

Encapsulation: A protective layer shields the sensor from premature degradation, ensuring reliable performance throughout its intended lifespan. Biodegradable waxes, silk fibroin, or hydrophobic coatings are commonly used, and their composition can be tailored to control the sensor’s decomposition rate for specific environmental conditions

Biodegradable Sensor Fabrication

To achieve scalability and cost-effective production, biodegradable sensors are often fabricated using additive manufacturing techniques. These methods enable precise material deposition, minimize waste, and are compatible with biodegradable materials, making them ideal for sustainable sensor development.

Screen Printing: A widely used, cost-effective technique that deposits conductive inks onto biodegradable substrates. Screen printing supports high-throughput production of patterned electrodes with excellent reproducibility, making it suitable for mass manufacturing.

Inkjet Printing: Enables precise deposition of conductive inks and biomaterials, allowing the creation of high-resolution, customizable sensor arrays. This method is ideal for fine-feature patterns, multi-layered structures, and the integration of functional biodegradable polymers.

Roll-to-Roll Processing: A continuous, scalable approach for producing flexible biodegradable sensors. It is particularly suited for large-scale applications, combining cost efficiency with consistent quality, and facilitating integration into agricultural and environmental monitoring platforms.

By leveraging these additive manufacturing methods, biodegradable sensors can be produced at scale, tailored to specific environmental conditions, and incorporated into precision agriculture systems with minimal ecological impact.

Applications of Biodegradable Sensors

Biodegradable sensors offer a wide range of applications in agriculture, providing real-time, field-deployable data that enhance efficiency and sustainability. Key areas of impact include:

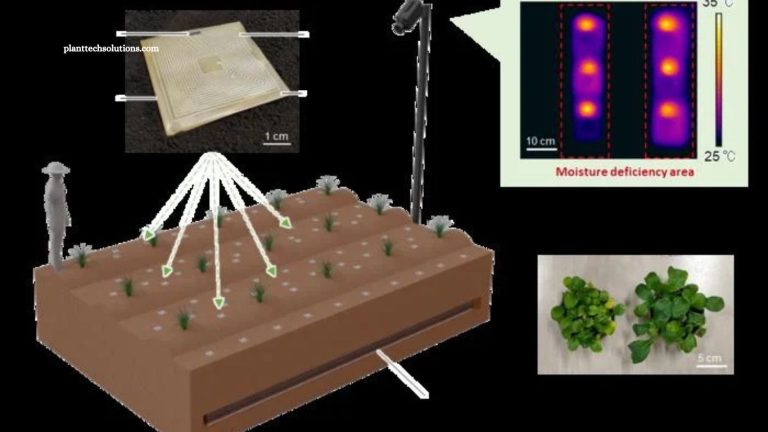

Soil Moisture Monitoring for Irrigation Optimization:

Water scarcity poses a significant challenge in farming, as both over- and under-irrigation can harm crops. Biodegradable sensors detect soil moisture fluctuations, allowing farmers to fine-tune irrigation schedules, reduce water waste, and maintain optimal plant hydration, improving yields and lowering costs.

Nutrient Availability and Fertilizer Management:

Monitoring soil ion concentrations, particularly nitrogen, phosphorus, and potassium (NPK), enables precise fertilizer application. Biodegradable sensors minimize nutrient leaching, reduce environmental contamination, and improve soil fertility for healthier, more sustainable crop production.

Microbial Activity and Soil Health Monitoring:

By tracking changes in conductive matrix degradation, these sensors provide insights into microbial activity, soil respiration, and enzymatic functions. This information helps optimize crop rotations, implement regenerative practices, and maintain long-term soil productivity.

Detection of Soil Contamination and Degradation:

Sensors embedded with ion-selective materials can detect heavy metals, pesticide residues, and salinity. Early warning of contamination supports proactive soil management, protecting crops and the environment.

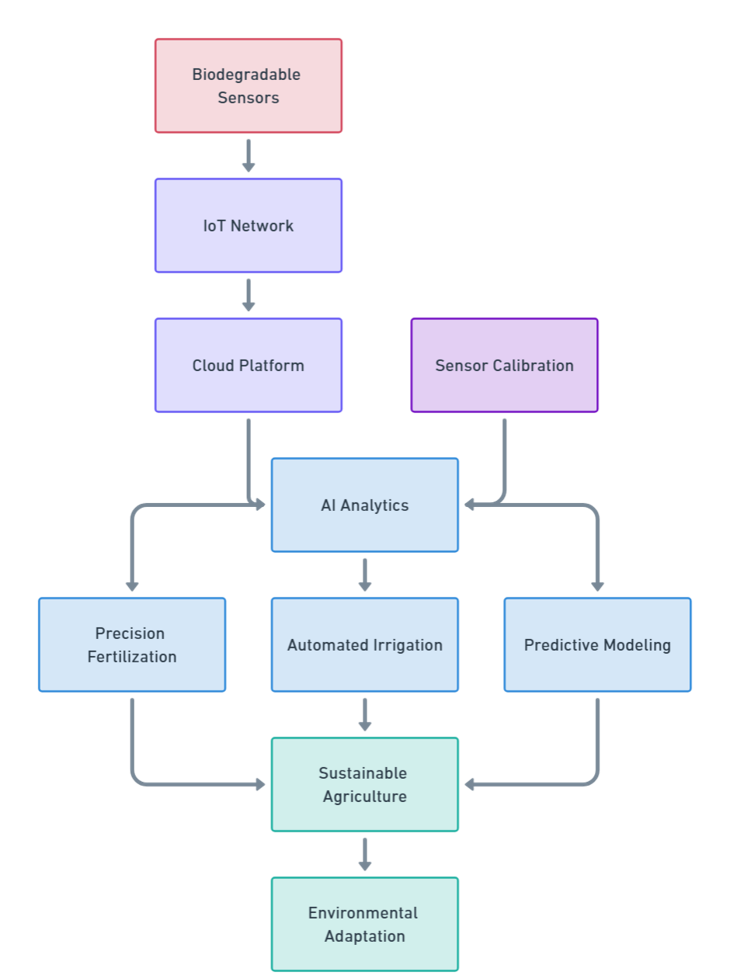

Smart Farming and IoT Integration:

Connected to IoT networks, biodegradable sensors enable remote soil monitoring, automated irrigation, precision fertilization, and AI-driven analytics. This integration reduces labor, enhances predictive decision-making, and promotes a technologically advanced, sustainable agricultural system.

The Path Forward

As the pressure to farm sustainably intensifies, agriculture is entering a pivotal decade, shaped by breakthroughs in microbial fertilizers, the rise of regenerative practices, and increasing demand for traceability and measurable environmental outcomes.

Biodegradable sensors, once limited to academic research and proof-of-concept trials, are now poised to play a central role in this transformation. Their value extends beyond reducing waste—they enable a new generation of short-term, in-field monitoring tools that match the pace of modern farming. From tracking early-stage performance of biological inputs to assessing soil response over a growing season, these sensors provide timely, localized, and actionable insights.

Innovation alone, however, is not enough. To achieve broad adoption, sensors must integrate into systems that handle the variability of real-world farms, generate actionable data, and support informed decisions for growers, agronomists, and researchers.

BioSensor Solutions is positioning itself in this niche. With its real-time soil monitoring platform in early deployment, the company is building the infrastructure necessary for biodegradable sensors to be effective at scale. By aligning with key agricultural trends—from biological nitrogen management to data-driven regenerative practices—BioSensor Solutions is not just preparing for the future of farming; it is helping to define it.

Frequently Asked Questions (FAQs)

What are biodegradable sensors?

Biodegradable sensors are electronic devices made from materials that naturally decompose in the environment. They monitor soil conditions, moisture, nutrient levels, and other parameters without leaving harmful residues.

How do they work?

They consist of three main components: a biodegradable substrate for structure, a functional conductive element that detects changes in soil properties, and an encapsulation layer that controls sensor longevity. Changes in electrical properties, such as resistance, provide real-time environmental data.

What are their main applications in agriculture?

Key applications include soil moisture monitoring, nutrient and fertilizer management, microbial activity tracking, detection of contaminants, and integration into IoT-based smart farming systems.

How are they fabricated?

Biodegradable sensors are often produced using additive manufacturing methods like screen printing, inkjet printing, and roll-to-roll processing, which allow for scalable, cost-effective, and sustainable production.

Why use biodegradable sensors instead of traditional sensors?

They reduce environmental impact, provide real-time, in-field monitoring, and eliminate the need for retrieval or disposal, making them ideal for sustainable precision agriculture.

Can they be integrated into existing farm systems?

Yes. Many biodegradable sensors are designed for IoT connectivity, enabling seamless integration with automated irrigation, fertilization systems, and data analytics platforms.

Conclusion

Biodegradable sensors represent a transformative step toward sustainable, data-driven agriculture. By providing real-time, localized insights into soil moisture, nutrient levels, microbial activity, and contamination, these sensors empower farmers to make informed decisions that optimize crop yields, reduce resource waste, and minimize environmental impact. Their temporary, eco-friendly design eliminates the need for retrieval, aligning perfectly with the principles of regenerative and precision farming.